Tests must be carried out under IEC 62446 and IEC 60891 to monitor and measure the performance of solar power plants. These tests are mainly IV-Curve measurement, drone thermal tests, EL (electroluminescence) test, insulation test, grounding test and performance measurement. Below you can see what information you will receive as a result of these measurement and inspection services. Please send an email to [email protected] to receive an audit service from us.

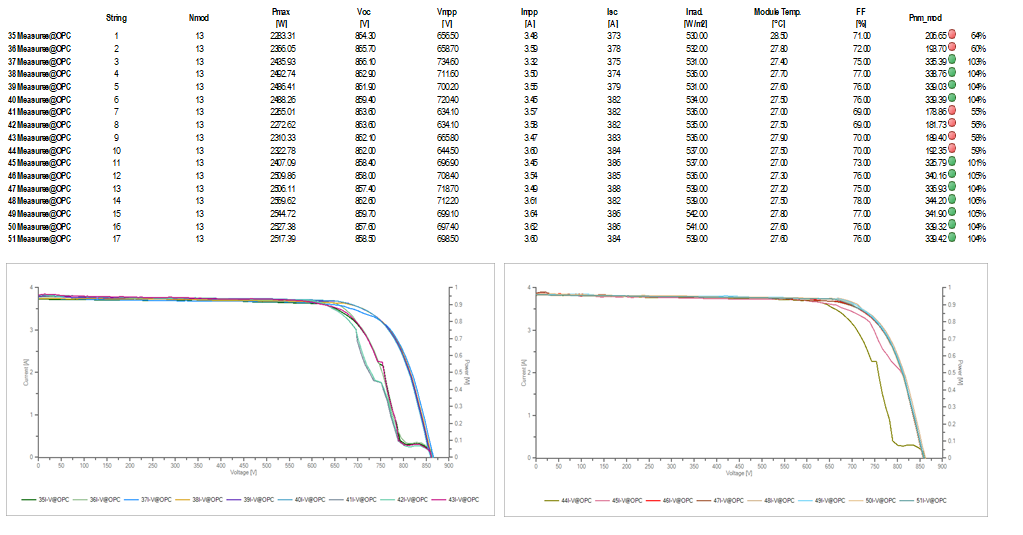

1- IV-Curve Measurement – IEC 60891

As a result of the IV Curve measurement below, you will see the IV curve measurements of all the solar panel arrays in the field. we can check if there is a problem. These metrics also serve as a registry, and will help you to see how small the solar panels are in the future. Solar panel, the solar power plant is missing the answer to the question about the answer to the part of the solar panels with this test.

As a result of the IV test, you can have information about:

- Find out the actual strength of your panels. You can check whether it is consistent with the factory data.

- Do you have any losses from LID (Light induced degredation) in your solar panels?

- Is there a loss of PID (Potential induced degredation) in your solar panels?

- Your DC cables have ground contact or leakage due to any cut / mouse ingestion

- Are there any problems with the by-pass diodes of your solar panels?

- Detection of shading problems

- Possible faulty connections in panel series

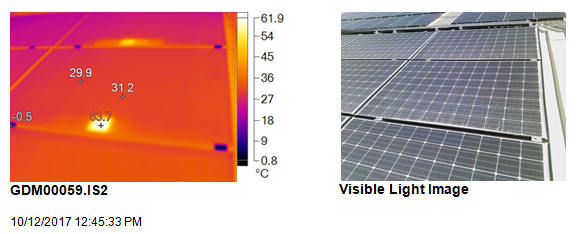

2 – Hot-spot Measurement with Drone – IEC 62446 / IEC 61215

Hot-spots may occur after the solar panels are switched on. Again we perform this control with both drone and hand thermals. At this stage, you can declare the IS2 files given to us by the software to the panel factory. The thermal monitoring of solar power plants is important in determining the problems.

As a result of the thermal measurement, you can have information on the following subjects;

- Do I have damaged cells in my solar panels

- Is there an unexpected warm-up in panel materials such as bypass diodes, junction-boxes?

- Did shading environmental factors damage panels?

- Do you have any unattended arrays

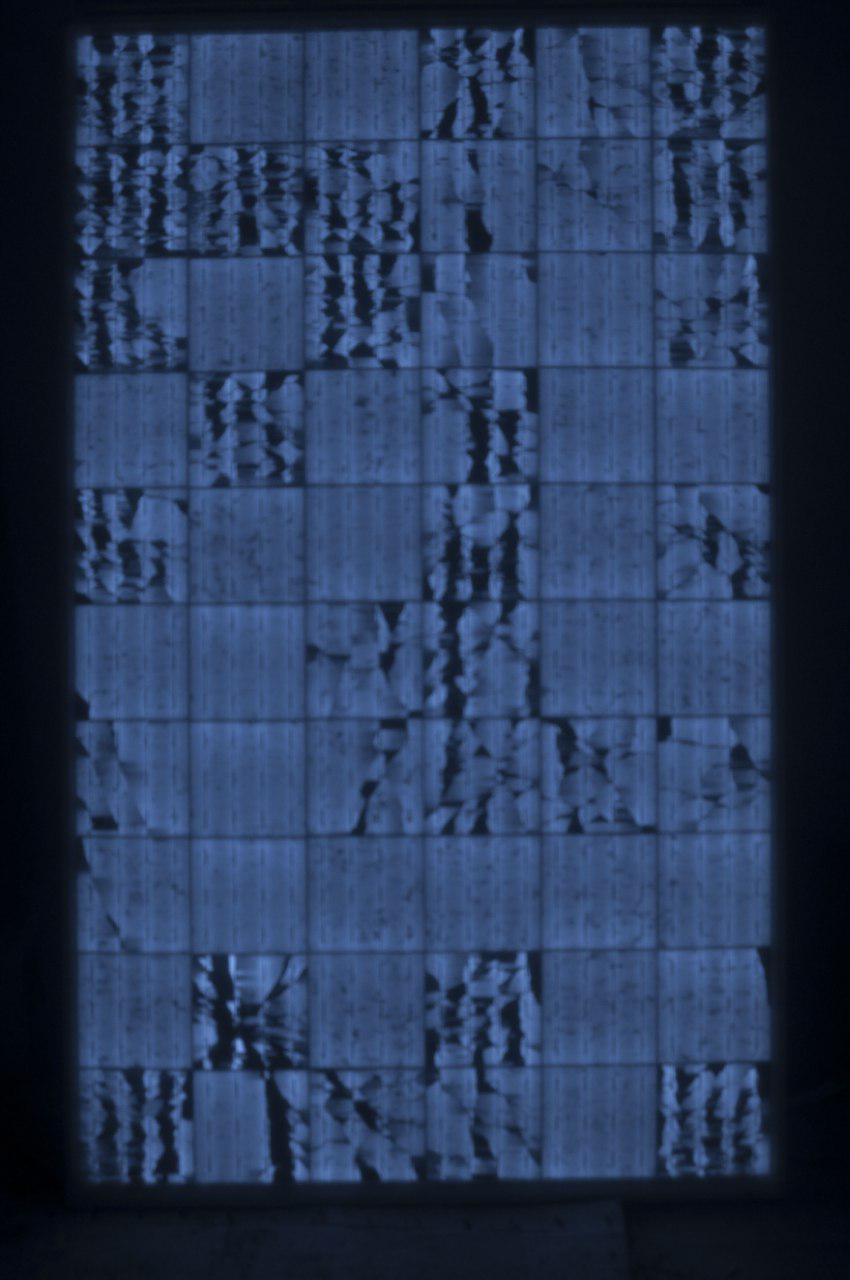

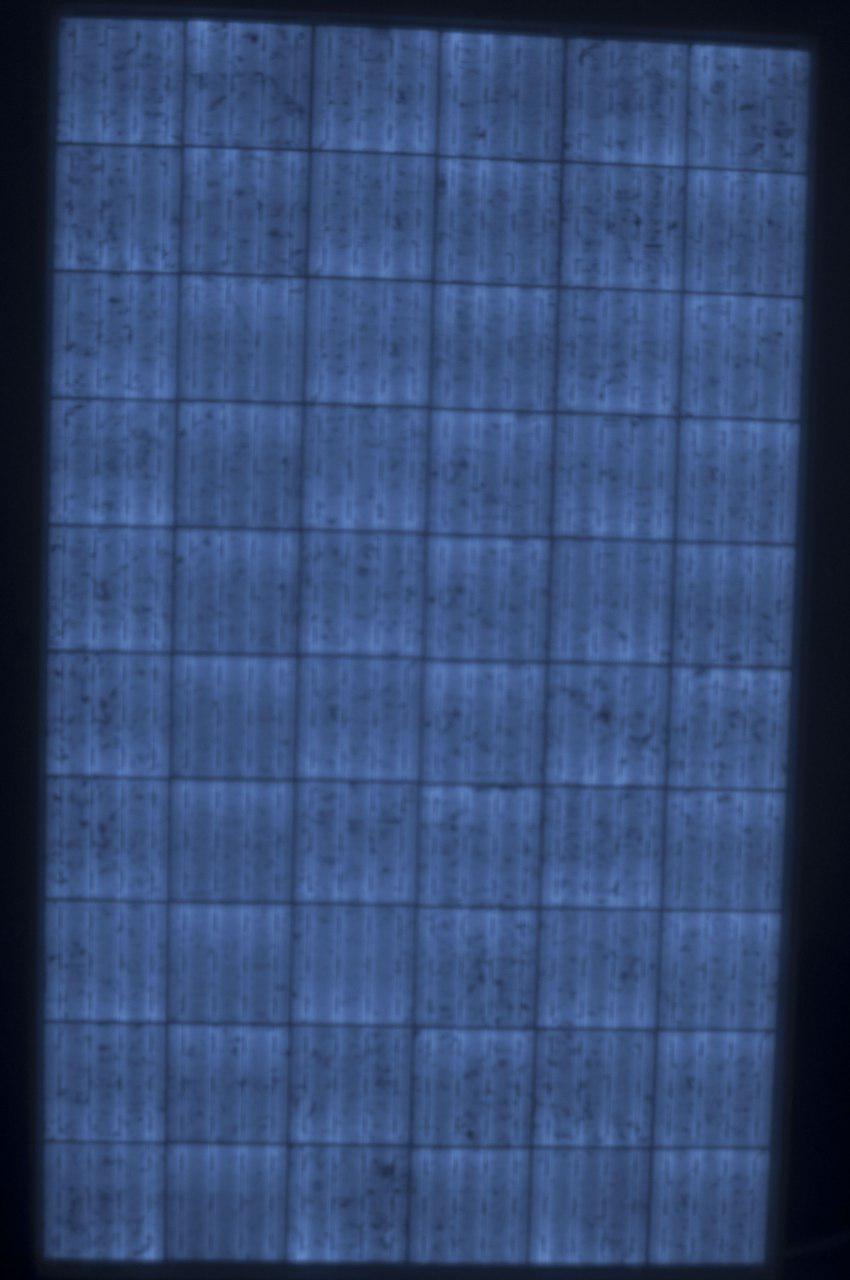

3 – EL (electroluminescence) Test of Solar Panels – IEC 61215 / IEC 61646

EL panels of solar panels are presented to the customer. The future occurrence of the cells used in this phase can be considered as an x-ray with respect to probable problems. You can see whether the cells are damaged during both manufacturing and GES installation.

|

|

As a result of this measurement, you can learn about:

- Structure of cells

- A broken in cells v.s. whether

- Impacts or overheads during overhead EPC installation

- This test does not give you information about the strength of your panel. It can only give information about its source if there is a problem in the IV curve measurement.

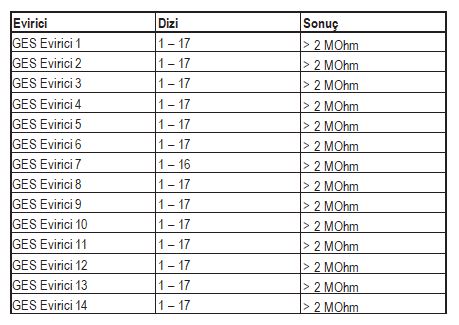

4 – Insulation Tests – IEC 62446

Solar panels are subjected to a voltage of 1.000V and the insulation resistance between Panel-Ground is examined. This is important in order not to have any leakage on the panels and not to cause any harm to the people and also to prevent the inverters from being switched off. The damage caused by the EPC companies during the wiring process is also determined at this stage and is very important during the commissioning process.

As a result of this measurement, you can learn about:

- Do you have any damage to your cables?

- Is there any phase-to-earth fault on the DC current side of the solar panels?

- Is there any problem affecting the insulation resistance to disable your inverter?

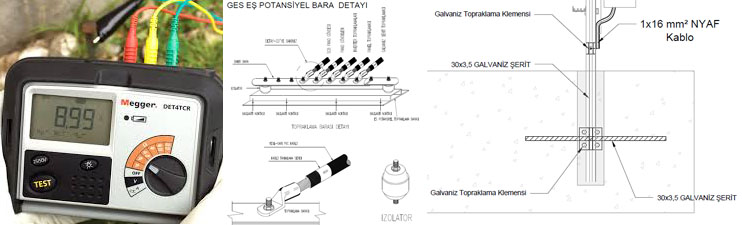

5 – Earthing Measurement

Grounding is of great importance in all electrical installations, especially in solar power plants. Grounding is of great importance both in leakage current protection and in general protection especially in lightning in the power plant. A disconnection in grounding and co-potentials can cause serious damage to the system. In this context, the megger grounding measurement of the equipotential busbar should be recorded by carrying out earthing measurements of both the construction and the solar panels and the necessary measures should be taken in case the problem is detected.

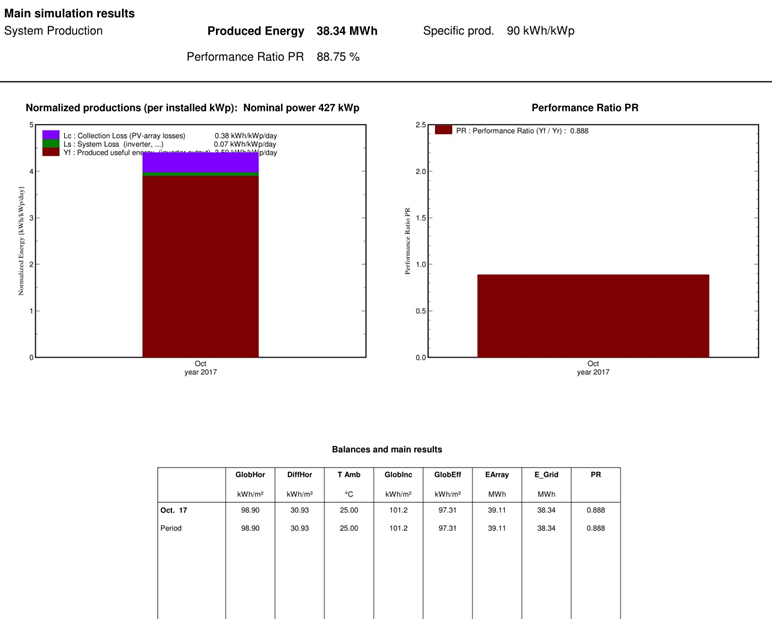

6 – PVSYST Simulation Using Actual Values

Based on the recorded radiation and panel temperature data of the power plant, simulation is performed on the software by using PAN files presented by the manufacturer of the panel and compared with the energy produced and produced. With these results, it is examined whether the system is overlooked (transformer, inverter, etc. losses) and a general production expectancy profile is extracted. As a result of this test, a system-wide problem is checked. With this calculation, the performance of solar power plant is measured and the performance value of the power plant is determined.

Following this study you will get the following results:

-

- How much your plant should produce according to the data we have

- Performance measurement of our power plant. How strong is our power plant?

</ ul>